Laser cutting technology has transformed the way industries shape, design, and fabricate materials with unmatched accuracy and consistency.

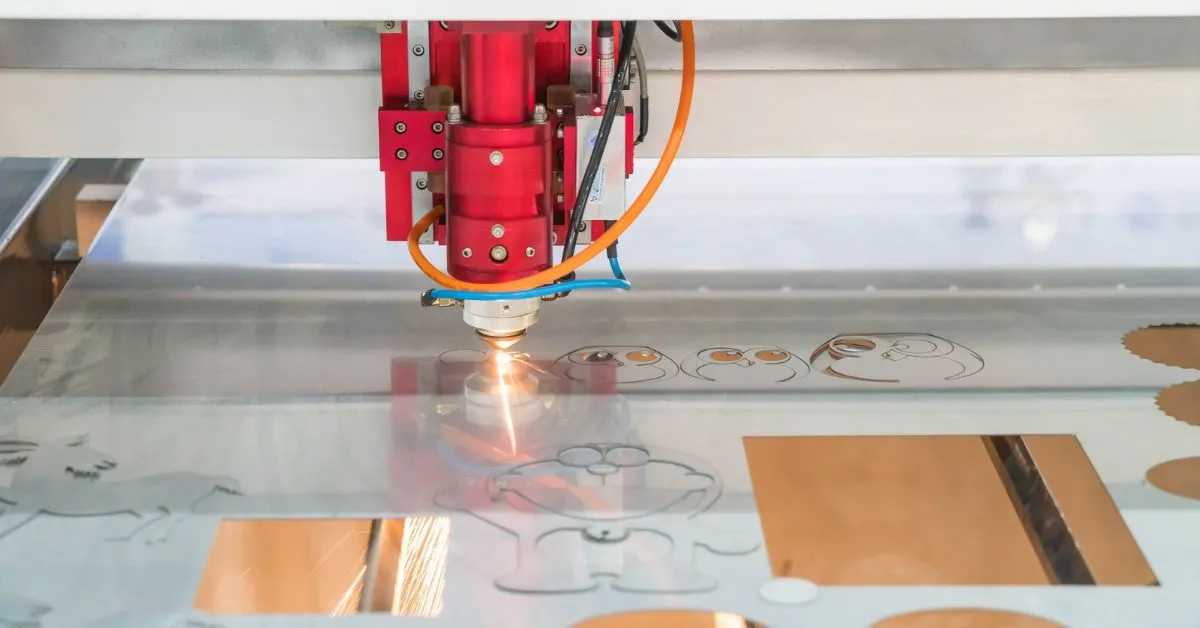

Laser cutting machines use a highly focused laser beam to cut metals and non-metals with extreme precision. Unlike traditional cutting methods, laser cutting ensures clean edges, minimal material wastage, and high repeatability, even for complex designs.

One of the biggest advantages of laser cutting is its micron-level accuracy. This allows manufacturers to maintain consistent quality across large production volumes. It also reduces the need for secondary finishing processes, saving both time and operational costs.

Looking to upgrade your manufacturing precision with advanced laser cutting solutions? Contact Unique Laser today to explore high-performance laser cutting machines designed to meet your specific industrial requirements. Our experts are ready to help you achieve superior accuracy, efficiency, and productivity.

Laser cutting is widely used in industries such as automotive, electronics, metal fabrication, medical devices, and aerospace. The technology supports faster production cycles, better dimensional accuracy, and improved design flexibility.

By adopting laser cutting machines, manufacturers can achieve higher productivity, superior product quality, and long-term cost efficiency, making it a smart investment for modern production facilities.

Frequently Asked Questions

Laser cutting machines can cut a wide range of materials including stainless steel, mild steel, aluminum, copper, brass, acrylic, and other non-metals with high precision.

Laser cutting offers micron-level accuracy, far superior to traditional cutting methods, ensuring consistent quality and minimal dimensional errors across production batches.

Yes, laser cutting produces narrow kerf widths and clean cuts, which significantly reduces material wastage and improves overall material utilization.

Absolutely. Laser cutting machines are ideal for both high-volume manufacturing and customized production due to their speed, repeatability, and automation capabilities.

Industries such as automotive, electronics, aerospace, medical devices, metal fabrication, and precision engineering benefit greatly from laser cutting technology.

Conclusion

Laser cutting has become a game-changing technology in modern manufacturing by delivering exceptional precision, consistency, and efficiency. Its ability to handle complex designs, reduce material wastage, and maintain tight tolerances makes it an ideal solution for industries aiming to improve product quality and productivity.

By integrating laser cutting machines into their production processes, manufacturers can stay competitive, reduce operational costs, and meet the growing demand for precision-engineered components. Laser cutting is not just a technological upgrade—it is a strategic investment for long-term manufacturing success.