Laser marking and laser engraving technologies have become essential tools for industries that demand permanent, precise, and high-quality markings.

Laser marking uses a focused laser beam to create permanent marks such as serial numbers, barcodes, QR codes, logos, and batch information on a wide range of materials. Unlike ink-based or mechanical marking methods, laser marking is contactless, fast, and maintenance-free, ensuring long-lasting results without damaging the material surface.

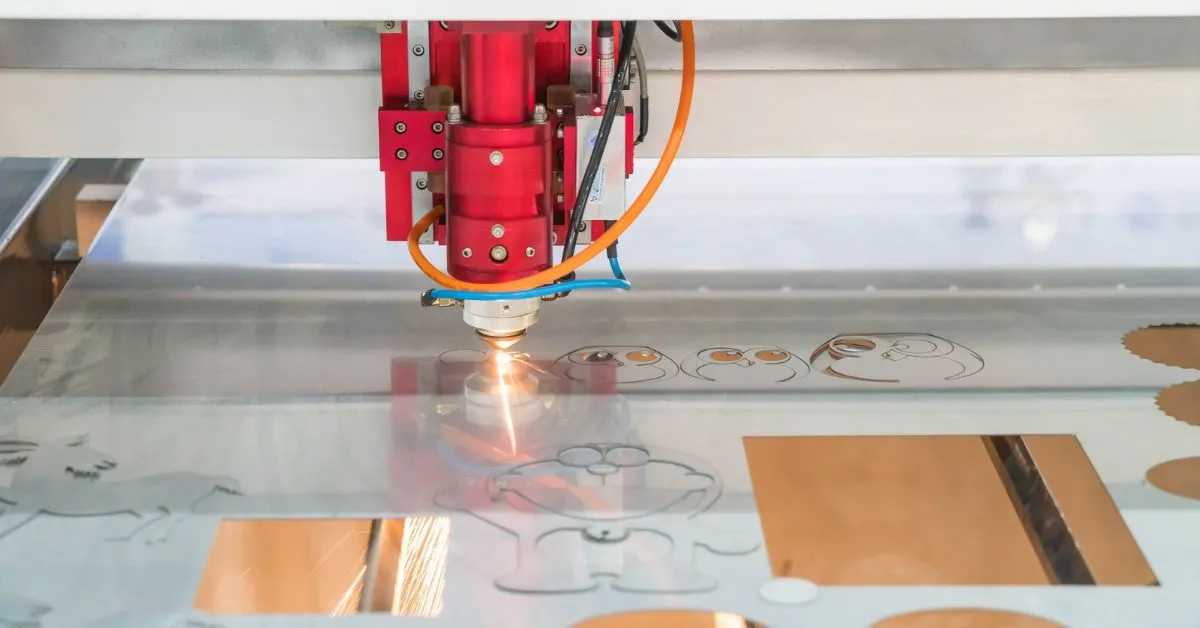

Laser engraving goes a step further by removing a thin layer of material to create deep, durable, and highly visible markings. This process is ideal for applications where marks must withstand harsh environments, wear, and chemical exposure.

Need reliable and high-precision laser marking or engraving solutions for your industry?

Get in touch with Unique Laser today to explore advanced laser marking and engraving machines tailored to your production needs.

One of the biggest advantages of laser marking and engraving is regulatory compliance and traceability. Many industries rely on laser technology to meet international quality standards and ensure full product tracking throughout the supply chain.

With high speed, minimal operating costs, and exceptional marking clarity, laser marking and engraving machines help manufacturers enhance product value, brand identity, and operational efficiency.

Frequently Asked Questions

Laser marking alters the surface of the material to create marks, while laser engraving removes a small amount of material to create deeper, more durable markings.

Laser machines can mark and engrave metals, plastics, ceramics, glass, leather, and coated materials depending on the laser type.

Yes, laser markings and engravings are permanent and resistant to wear, heat, chemicals, and abrasion.

Absolutely. Laser marking systems are fast, automated, and ideal for mass production with consistent quality.

No. Laser marking and engraving machines do not require inks, chemicals, or consumables, making them cost-effective and eco-friendly.

Conclusion

Laser marking and engraving have become indispensable technologies for industries seeking precision, permanence, and productivity. From traceability and compliance to branding and customization, laser solutions deliver unmatched performance across diverse applications.

By adopting laser marking and engraving machines, manufacturers can improve efficiency, reduce operational costs, and ensure long-lasting product identification—making it a smart investment for future-ready manufacturing.