Hendhel Fiber Laser Welding Machine

Key Features

Application Scope

Specification

| DEVICE / MODEL | 1500W | 2000W | 3000W | 6000W |

| Laser Wavelength | 1080 (+10) nm | 1080 (+10) nm | 1080 (+10) nm | 1080 (+10) nm |

| Output Fiber Length | 10M | 10M | 10M | 10M |

| Max Laser Bower | 1500W | 2000W | 3000W | 6000W |

| Rated Power | 7KW | 8KW | 11KW | 18KW |

| Supply Voltage (V) | 220V / 50HZ | 220V / 50HZ | 400V / 50HZ | 400V / 50HZ |

| Spot Adjustment Range | 0.1-5mm | 0.1-5mm | 0.1-5mm | 0.1-5mm |

| Laser Frequency | 1-10000HZ | 1-10000HZ | 1-10000HZ | 1-10000HZ |

| Cooling System | HC1500 | HC2000 | HC3000 | HC6000 |

| Observing System | Red Light | Red Light | Red Light | Red Light |

Frequently Asked Questions

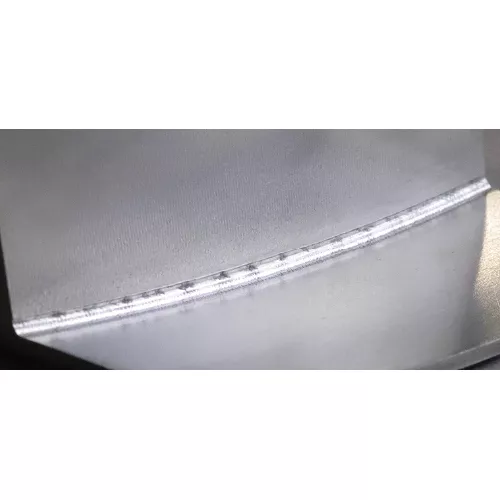

What is fiber laser welding refers to a welding process that uses a high-energy fiber laser beam to melt and fuse metals with high precision, deep penetration, fast speed, and minimal heat distortion.

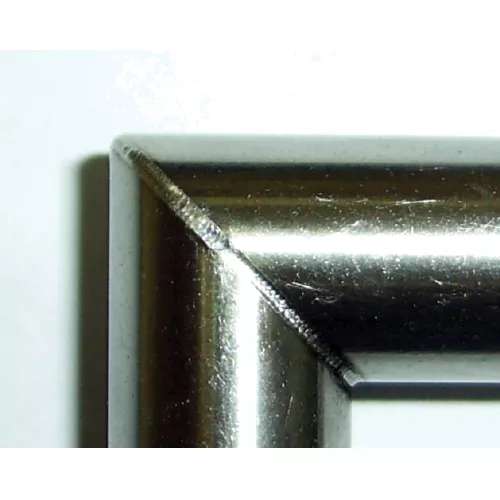

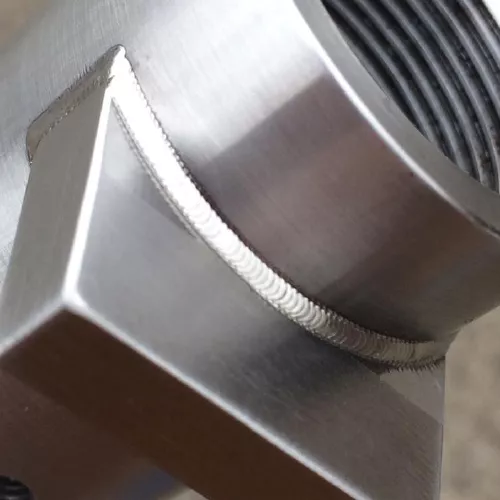

A handheld fiber laser welding machine provides flexibility, portability, clean weld seams, low deformation, and easy operation, making it ideal for complex and irregular welding tasks.

A handheld fiber laser welding machine can weld stainless steel, carbon steel, aluminum, brass, and other metal alloys commonly used in industrial fabrication.

Handheld laser welding machine installation is simple and fast. The system is typically plug-and-play, requiring only proper power supply, cooling connection, and basic parameter setup.

A handheld fiber laser welding machine is widely used in kitchen cabinets, stainless steel furniture, doors and windows, stair railings, electrical enclosures, and metal fabrication workshops.

Download Brochure

Contact With Us

Spares & Consumables

Keep your operations running smoothly with our extensive range of high-quality laser spares and consumables.